We buy for many reasons. If given the opportunity and authority to choose, we can make good decisions provided we take a little time and think it through. Some of the basic reasons why we buy are:

- To reduce the time and labor costs to fix, build or make something more reliable.

- To save money, both direct costs and indirect costs by being more productive.

- To improve safety and health.

- For cosmetic or design

- Because of the prestige of the product.

- Product or service provides value-added contributions – we get more than expected.

- We are told to; we have external influences (Boss, corporate policy, or warranty).

- We buy for personal or internal reasons (experience or emotion).

You will be hard-pressed to find an example of something you have bought personally or professionally that does not fall into one or more of these categories. We will spend money, but we want to get something in return – a good product that does what it says it does or better yet, it does better than the claim and you get some unexpected bonuses. The sad truth is that in many industrial settings, logic and reason is replaced by external influences or emotions. We would never purchase the cheapest house paint or engine oil for our personal use. If we did, we surely would not repeat the practice. That is not the case in maintenance, repair and operations (MRO) spending. It is the industry norm to use price or brand names as a mitigating factor in the decision process. This is unfortunate because price is generally a poor reason to purchase an item. Price is an easy metric to understand. Often the buyer will confuse price with cost. Worse yet, the difference between the cost to purchase and the cost to own are very different indeed.

These buying decisions should be based on a combination of experiences and logic, but that is not always the case. There are instances when we buy specific items because we have no choice in the matter. The part may be specific to a tool or machine where the original equipment manufacturer (OEM) specifies the performance or dimensional aspects. Often there is little room for deviation. Sometimes, the decisions are taken out of our hands entirely. The corporate headquarters may have negotiated a deal with a national vendor for the lowest price disregarding quality, performance or worse, specifications. A growing trend in industry is to centralize the purchasing of maintenance, repair, and operation items. The corporate headquarters may negotiate the best price and delivery terms and pass that “savings” on to other divisions and departments. In theory if the purchasing requirements are comprehensive, this can make sense if all products are of equal performance and the vendors are required to provide services that compliment the mission of the organization. This book will explain how purchasing, maintenance, or the engineering departments can develop purchasing specifications that will ultimately drive reliability and reduce overall spending.

The common factor that influences a purchasing decision is typically price. Lowest bid gets the job. We all know that this is a very dangerous practice. Unless the engineering, production, and maintenance teams get involved in the purchasing requirements and part/product procurement specifications, this practice will continue; productivity along with reliability will never reach levels we all know are obtainable. What happens when other teams get involved and attempt to assist in the procurement process? The input of other teams can be invaluable.

The job of the buyer or purchasing agent has evolved over the past decade due to the internet. More businesses are using lean manufacturing practices, which require just-in-time (JIT) inventories. If a manufacturing line is down because of a failed part or tool then the company could lose tens of thousands of dollars, as well as customers. Some buyers or purchasing agents will attend conferences or trade shows for the products that take a certain degree of sophistication to purchase. These products are vital to the organization (such as an integral ingredient or a device). Many buyers rely on the requisitioner to know what they need for the non-vital items. Often a requisition will come in for an MRO item and the buyer resorts to using a distribution house to provide the appropriate item. The decision comes down to price and availability. Many companies with success are now using procurement cards. Establishing this practice has streamlined the purchasing process. Most of the purchasing transactions are now automated using electronic purchasing systems that link the supplier and firms together through the Internet. There is still room for improvement in this process.

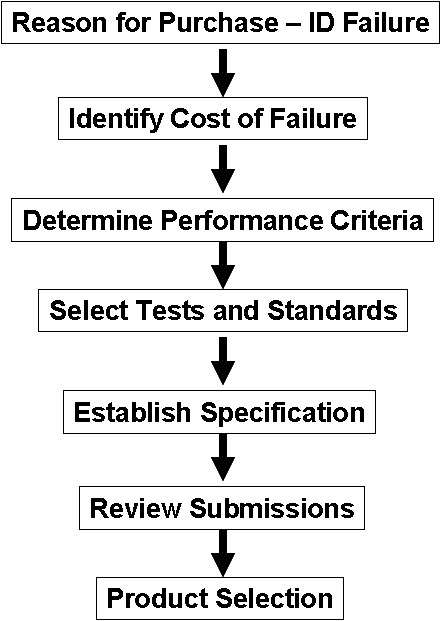

The buyer has never been in a better position to demand performance from a vendor. It is important that you require your vendors to comply with your needs by making procurement specifications that not only take price and performance into account, but also contribute to the reduction of direct and indirect costs. The question remains – “How do I know just what to buy” and more importantly “How can I assure that what I am buying will actually help me”? The process of:

- Identifying the Reason for the Purchase (relieve failure)

- Identify What Products are Costing The Most Due to Failure

- Determine the Performance needed to Last Longer

- Choose What Product Test Results and Standards Best Suit Your Situation

- Build The Specification

- Review Product Submissions

- Select the Product and Monitor

For those who like flow charts, consider the flowing process map image.

Anyone engaged in the purchasing process has to have a sense for value and can appreciate that in certain instances a more expensive product will have to be purchased. This is because they recognize that the buying criteria are performance with the ultimate goal to drive down the cost of failure due to equipment downtime, repair labor and parts replacement.

You must first understand cost and value before you can appreciate the cost of failure. In order to properly document your product requirements, you must also understand why things fail. Understanding the fundamental sources of failure will help you to discern from the marketing collateral as well as the spin, hype and misinformation that will be presented to you by vendors and associates. Yes, even your fellow employees will have a favorite product that they like and it may be for all the wrong reasons. Having a firm understanding of cost, value and failure shall help you in countless ways. Applying your knowledge of value, cost and failure will allow you to begin the process of establishing a specification.